For thermal property evaluation of anisotropic and composite material! Thermo Wave Analyzer TA35, which can measure XYZ directions continuously.

I am KATO chan at Osaka Laboratory.

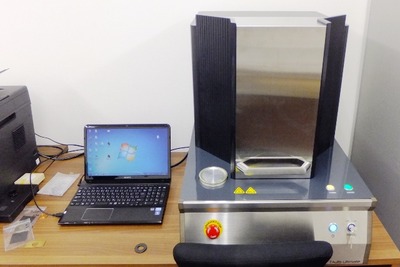

I’m going to introduce “Thermo Wave Analyzer TA” anew.

https://hrd-thermal.jp/en/apparatus/ta.html

“Thermal property measurement equipment Thermo Wave Analyzer TA”, main product of Hudson Laboratory, which is not very well-known yet. Just as the name, the equipment to measure “Thermal property (Thermal diffusivity)”

By periodical heating radiation-temperature measuring method, measuring “Thermal diffusivity” of the material.

https://en.wikipedia.org/wiki/Thermal_diffusivity(wiki)

We have totally 4 products on line up, from TA31/32 with necessary function to TA35 with full function. This time, I introduce the highest model “TA35”.

TA35 has 3 big characteristic points as follows.

1. High flexibility on sample shape

At first, I show you the sample stage of TA35.

You can see the ring in the center of the sample stage.

The detached ring is here↓↓↓

There is a hole in the center of the ring. Only by putting the sample on this ring, sample setting is completed.

The measuring point must be in the center of the hole. If so, the setting is OK.

After sample setting↓↓↓

This is OK

This is also OK, because the sample reaches the center of the hole.

For measuring small sample, we have ring versions with smaller hole. The ring with the smallest hole on the right of the photo is specialized for small sample.

Sample shaping is not necessary, so preparation is quite easy. Because you just need to put the sample as it reaches the center of the sample stage ring.

(However, you need to consider the influence of the edge)

2. Anisotropic sample can be measured

In general, equipment for thermal property measurement is only for vertical direction(Z).

(For example, laser flash method)

In contrast, on Thermo Wave Analyzer TA35, measurement for both vertical(Z) and horizontal(XY) directions is possible.

Periodical heating on the point

Continuous measurement for different directions is possible, therefore you need only to wait after sample setting. This is easy operation. In addition, measurement for XYZ directions is possible with one sample, so you do not need to prepare sample for each direction. Thanks to it, it takes half time to prepare the sample.

That’s why I can say TA35 is very suited to evaluate anisotropic materials such as Graphite Sheet, TIM and etc. I recommend trial measurement if the sample is expected to be anisotropic.

Distribution can be evaluated by repeat measurement for vertical(Z) direction. The fact that “heating and detecting area is very small point” makes it possible. (The point is approx. φ500μm)

Therefore distribution in the sample can be evaluated.

Recently resin material mixed with filler for higher thermal conductivity is increasing. Even though you expect that materials are mixed evenly by machine, that is sometimes uneven on thermal property. That is not quite sure because of materials, orientation, and production method.

How is the distribution on the sample on actual production? Have you thought that “if I can see and confirm the distribution”……..?

By Thermo Wave analyzer TA35 evaluation, you can confirm on the display like this.

https://hrd-thermal.jp/en/res/pdf/unique/apparatus/apparatus-ta.pdf

I have explained only good points. I will also mention impossible samples to measure.

Too thick sample

Measurement range of thickness is different by material and direction

Non-fine solid

For example, foam. Thermal diffusivity can’t be measured because of air.

High thermal conductivity, less than φ10mm

Too small to put on the sample stage. High thermal conductivity brings edge influence. No result can be obetained.

Even you think the sample may be impossible sample, please consult us once. We will propose another measurement method or something.

Any request, proposal, question would be all welcomed.

https://hrd-thermal.jp/en/contact/

I’m going to introduce “Thermo Wave Analyzer TA” anew.

https://hrd-thermal.jp/en/apparatus/ta.html

“Thermal property measurement equipment Thermo Wave Analyzer TA”, main product of Hudson Laboratory, which is not very well-known yet. Just as the name, the equipment to measure “Thermal property (Thermal diffusivity)”

By periodical heating radiation-temperature measuring method, measuring “Thermal diffusivity” of the material.

What is “Thermal diffusivity”……….

“Thermal diffusivity” is the physical property that is usually used to acquire steady-state thermal gradient on heat transfer phenomenon.https://en.wikipedia.org/wiki/Thermal_diffusivity(wiki)

We have totally 4 products on line up, from TA31/32 with necessary function to TA35 with full function. This time, I introduce the highest model “TA35”.

TA35 has 3 big characteristic points as follows.

- High flexibility on sample shape

- Anisotropic sample can be measured

- Distribution can be seen

1. High flexibility on sample shape

At first, I show you the sample stage of TA35. |

| The sample is not set yet. |

You can see the ring in the center of the sample stage.

The detached ring is here↓↓↓

There is a hole in the center of the ring. Only by putting the sample on this ring, sample setting is completed.

This is OK

This is also OK, because the sample reaches the center of the hole.

For measuring small sample, we have ring versions with smaller hole. The ring with the smallest hole on the right of the photo is specialized for small sample.

|

| Hole diameter is φ20mm・φ10mm・φ5mm(From left to right) Normally we use φ20mm ring to avoid influence of the edge. |

2. Anisotropic sample can be measured

In general, equipment for thermal property measurement is only for vertical direction(Z).

(For example, laser flash method)

In contrast, on Thermo Wave Analyzer TA35, measurement for both vertical(Z) and horizontal(XY) directions is possible.

Periodical heating on the point

Continuous measurement for different directions is possible, therefore you need only to wait after sample setting. This is easy operation. In addition, measurement for XYZ directions is possible with one sample, so you do not need to prepare sample for each direction. Thanks to it, it takes half time to prepare the sample.

That’s why I can say TA35 is very suited to evaluate anisotropic materials such as Graphite Sheet, TIM and etc. I recommend trial measurement if the sample is expected to be anisotropic.

3. Distribution can be seen

Thermo Wave Analyzer TA35 has mapping function.Distribution can be evaluated by repeat measurement for vertical(Z) direction. The fact that “heating and detecting area is very small point” makes it possible. (The point is approx. φ500μm)

Therefore distribution in the sample can be evaluated.

Recently resin material mixed with filler for higher thermal conductivity is increasing. Even though you expect that materials are mixed evenly by machine, that is sometimes uneven on thermal property. That is not quite sure because of materials, orientation, and production method.

How is the distribution on the sample on actual production? Have you thought that “if I can see and confirm the distribution”……..?

By Thermo Wave analyzer TA35 evaluation, you can confirm on the display like this.

https://hrd-thermal.jp/en/res/pdf/unique/apparatus/apparatus-ta.pdf

- /- - /- - /- - /- - /- - /-

I have explained only good points. I will also mention impossible samples to measure.

Too thick sample

Measurement range of thickness is different by material and direction

Non-fine solid

For example, foam. Thermal diffusivity can’t be measured because of air.

High thermal conductivity, less than φ10mm

Too small to put on the sample stage. High thermal conductivity brings edge influence. No result can be obetained.

Even you think the sample may be impossible sample, please consult us once. We will propose another measurement method or something.

Any request, proposal, question would be all welcomed.

https://hrd-thermal.jp/en/contact/

Comments

Post a Comment